Problems We Solve

Another good example of very little insulation and no ventilation.

A roof like this that butts up against another roof cannot be effectively ventilated. The beauty of using foam is that its air seal and efficiency don’t require ventilation. Building Code also allows foam to be installed without ventilation.

This house has little to no insulation.

When you see the depth of the snow around the three edges of the roof being so different from the depth in the middle of the roof, you’ve got serious heat loss. It looks cool, but the gas bills for this house are likely not a laughing matter. To add insult to injury, this house is probably an oven in the summer.

This house is missing insulation in two attic cavities.

Can you guess which two are missing insulation?

Typical snow pattern on underinsulated roof.

When you see roof surrounded by snow in this pattern it is typically a cathedral or other sloped ceiling with only 5.5” of space between the drywall and the roof. Heat loss with fiberglass in that small of a cavity is extensive. Foam is much more effective and we can typically fix this in an existing home.

Swiss cheese snow pattern.

Snow melt doesn’t look like this unless there are huge gaps in the insulation. The areas with no snow have no insulation.

Energy-wasting, ineffective melt wires to prevent ice buildup in winter.

Ice is a sign of wasted energy, but the electricity needed for these melt wires wastes even more! Spray foaming the attic would get rid of the ice and eliminate the need for these wires (which often don’t work anyway).

“Flash n’ batt” foam hybrid system we fixed.

This customer pulled drywall down to install a gas line. The fiberglass he took down was soaked and the surface of the foam was wet (see rusty nails in picture). These systems need at least 2” of closed cell foam in WNY. Hiring someone inexperienced is expensive in the long run.

Severe insulation deficiency.

All of the low spots in the snow are due to melting from inside heat, which is not ideal. Cape style homes in our area are typically underinsulated and very difficult to ventilate. Spray foam eliminates these issues.

Severe insulation deficiency.

All of the low spots in the snow are due to melting from inside heat, which is not ideal. Cape style homes in our area are typically underinsulated and very difficult to ventilate. Spray foam eliminates these issues.

Severe insulation deficiency.

All of the low spots in the snow are due to melting from inside heat, which is not ideal. Cape style homes in our area are typically underinsulated and very difficult to ventilate. Spray foam eliminates these issues.

Spray Foam Insulation Applications

Closed Cell Application

Example of closed cell application in a retail store. We can typically make this application so flat that the average person can’t even tell it’s insulation.

Renovation, flat roof.

No way to ventilate so foam is the only option that will work well. All the heat produced by that can light is also forced down into living space when using foam.

New build, full envelope.

This is a completed job with walls shaved flush for installation of drywall.

A complete renovation job in the city of Buffalo.

These homes typically have gaps in the sheathing and all sorts of odd shaped cavities. Using anything but foam in these projects is highly ineffective and uncomfortable.

This is a crawl space that has no heat source in it.

It also isn’t connected to a basement. The best solution in that case is to spray the underside of the floor.

The rim joist in a crawl space (or basement for that matter) is the most important area in which to use foam.

It’s typically the biggest area for air infiltration in a house.

This is the most typical crawl space install.

These are usually connected to a full-height basement so we foam the three exterior walls and rims, install a vapor barrier on the floor, and leave the common wall between the basement and the crawl uninsulated and open. This approach allows relatively warm air into the crawl which gives homeowners a comfortable floor and an environment where those pipes won’t ever freeze.

Truss construction roof deck application.

Truss construction roof deck application. Using fiberglass batts in this situation would’ve been relatively ineffective. The first layer stapled to the bottom course is somewhat effective except for areas with can lights or bathroom fans, but the second layer that runs perpendicular to the first can’t possibly achieve a tight fit due to all the diagonal cross supports on the trusses.

Roof Foam and Coatings

Old roof in Buffalo that we remediated.

This is a rolled roof that they attempted to fix with “silver seal”. The huge low area you see cannot be stopped with that type of a system.

Another portion of the same roof.

Any dark spots are low areas. The seams every few feet really stand out in this picture.

Clean deck.

We power wash the roof deck to remove all dirt and anything else that keeps our coating from adhering and curing properly. The silver seal comes off with ease because it’s not a good long term solution.

Roofing foam was installed in any low areas to get rid of ponding.

We also used it around any roof penetrations and vents. Roofing foam is water proof.

Another portion of the roof that was too low and required foam to be installed.

Note that we didn’t insulate this entire roof because the building already had adequate insulation inside.

Acrylic was then installed to the roof.

The gray layer is the base coat and the white layer is the top coat. The customer is left with a seamless roof that will last several decades. The long term elasticity of the acrylic will expand and contract easily with the extreme changes in the WNY weather. The white roof will also make the building far more comfortable in the summer.

Roof insulation of an approximately 60 year old roof in Clarence.

This steel metal roof wasn’t in terrible shape, but the insulation in the building needed to be replaced and the owner wanted the roof to be exposed for aesthetics. By insulating from the top side we could provide that to him. This picture is early in process. Roof was power washed, rust areas were primed, and insulation was installed.

Roof insulation – progress.

Good progression picture. The far end has been insulated and coated with acrylic to protect the foam from the sun’s rays and to provide redundant waterproofing. The middle section only has foam installed. The close section hasn’t been insulated yet.

Roof insulation – foam action shot.

Foam must be covered with acrylic (the gray area) the day it is installed. Over time, the sun and weather will deteriorate the acrylic, at which point a new layer of acrylic is installed. Insulation does not have to be replaced. The warranty we provide is based on the thickness of the acrylic installed.

Roof insulation – progress.

This shows the same area as the last picture, but at the end of the day. The gray coat is a base acrylic coat. At least one more layer of acrylic (typically white) has to be installed over this layer. If a customer wants a longer warranty, then a third layer is installed.

Kittinger Furniture production facility, Clarence, NY.

Insulation over old rusty steel roof. No tear off was necessary. Insulation and a new roof added in the same step. The white acrylic topcoat also reflects most heat in the summer making the building much more comfortable and less expensive to cool.

Hyatt Place Commercial Project

Hyatt Place Project

The façade was then covered in brick, with an air gap in between the foam and the brick.

Additional Commercial Projects

Cellulose Insulation

Cellulose insulation.

Cellulose is often considered the most “green” insulation since over 90% of it is shredded recycled newspapers.

Cellulose installed to a trussed attic.

This is a much better solution than fiberglass batts since batts can’t achieve a proper tight fit around the diagonal cross supports of the trusses.

Retrofit Foam and Thermal Barrier Paint

Retro foam in wood framed closed cavity.

Holes drilled every cavity horizontally and every four feet vertically. This product is limited to homes and buildings with NO wall insulation, typically pre-1960s. Our dense packed cellulose product must be used for homes and buildings with small amounts of fiberglass (usually 1950s-1970s).

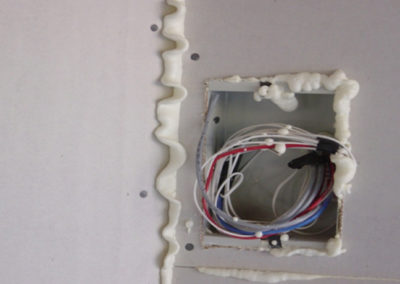

We find and seal every gap.

This is a picture of our retrofoam product, but is a great illustration of how effective all of our foam products are. The foam will find and seal every gap, thus controlling air infiltration and creating a comfortable home or office building.

Contact us today for a FREE consultation...

It’s our mission to sell and install the most cost-effective and efficient residential and commercial insulation products around.